Maintenance Tips to Maximize the Lifespan of Your Generator Set

What are the maintenance tips you should know to maximize the lifespan of a generator set?

- Perform routine oil and filter changes

- Check and clean the cooling system

- Test the battery and charging system

- Run the generator set periodically

- Inspect fuel quality and storage

- Schedule expert checks

Overview

- Power interruptions can severely disrupt operations, making reliable generator maintenance essential.

- Key practices include regular oil and filter changes, cooling system cleaning, battery testing, and periodic running to ensure optimal performance and longevity.

- Multico offers expert maintenance services that help keep your generator set in peak condition, preventing costly downtime and safeguarding your power supply.

Power interruptions often happen without warning, disrupting daily operations and putting critical activities on hold. For businesses and facilities, having a generator set ensures a dependable backup power source that keeps productivity and safety intact when the grid goes down. However, like any equipment, generators need proper care to remain reliable over the long term.

Fortunately, with consistent upkeep, you can prevent unexpected issues and extend the service life of your unit. In this article, we’ll share practical maintenance tips to help you maximize the lifespan of your generator set and keep it running smoothly whenever it’s needed.

Perform Routine Oil and Filter Changes

Like any engine-powered equipment, generator sets require regular oil and filter changes to keep their systems running efficiently. Over time, engine oil naturally breaks down and collects dirt, metal particles, and other contaminants that can cause excessive wear and reduce performance.

Routine changes—based on the intervals recommended by your supplier or manufacturer—help prevent these issues and keep the engine operating smoothly. Skipping this simple step can lead to costly repairs, sudden breakdowns, and downtime during critical moments when power is essential.

Depending on the brand and model, you can perform these changes yourself or seek professional servicing to ensure the job is done correctly.

Check and Clean the Cooling System

The cooling system is essential in preventing a generator’s engine from overheating, particularly during extended or heavy-duty use. Over time, dirt, debris, and mineral deposits can build up in the radiator and coolant passages, reducing the system’s ability to regulate temperature effectively.

To keep performance consistent, regularly inspect the radiator, coolant levels, and hoses for leaks or blockages. Cleaning the radiator fins and flushing the cooling system as recommended by the manufacturer will help prevent overheating and extend the lifespan of your generator set.

Test the Battery and Charging System

The battery is essential for reliable generator start-ups, especially during sudden power outages. Without proper care, even a well-fueled and well-serviced unit can fail to run when you need it most.

To avoid this, regularly check the battery’s charge, connections, and electrolyte levels (if applicable). Also, inspect the charging system to ensure it’s delivering the correct voltage, which helps prevent premature battery failure and keeps your generator ready for operation.

For added assurance, Multico offers load bank testing that pushes your generator set to 100% capacity under real-world conditions. This rigorous evaluation uncovers hidden issues before they become costly failures, ensuring your equipment consistently delivers reliable power when it matters most.

Run the Generator Set Periodically

Leaving a generator idle for long periods can cause problems like fuel degradation, battery drain, and moisture buildup inside the system. Running it at scheduled intervals helps keep internal components lubricated, prevents seals from drying out, and ensures the battery stays charged.

Make it a habit to operate your unit under load at least once a month. This not only circulates fluids but also allows you to spot small issues before they turn into costly repairs. Issues you can spot are unusual noises or slow starts. Regular exercise keeps your generator reliable and ready whenever an outage occurs.

Inspect Fuel Quality and Storage

Fuel quality directly impacts a generator’s performance and longevity. Contaminated fuel can cause clogging, corrosion, and inefficient operation, which may lead to costly repairs. This is why regular inspection is critical. You need to watch for signs of water, sludge, or microbial growth, especially when fuel has been stored for extended periods.

Proper storage practices also play a key role in preserving fuel quality. Always keep fuel in clean, sealed containers, and store them in cool, dry locations to slow down deterioration. By maintaining uncontaminated fuel, you ensure your generator runs efficiently and reliably whenever it’s needed.

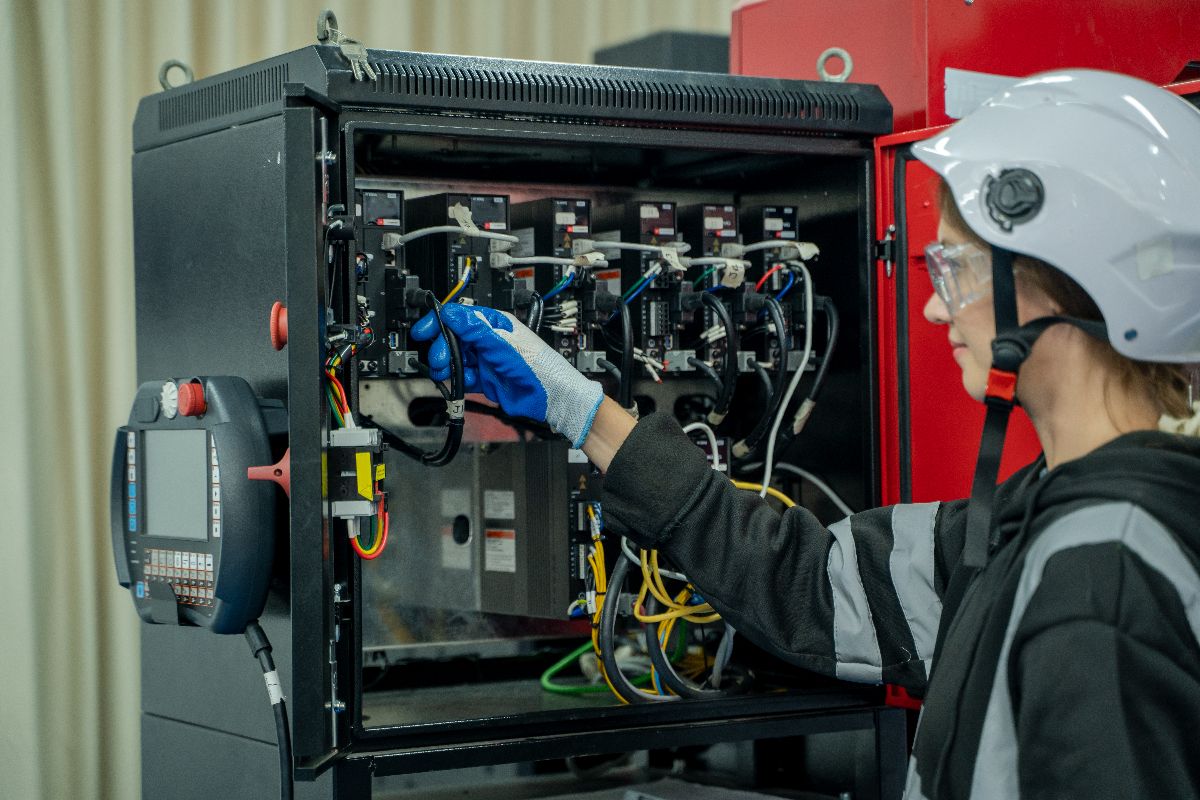

Schedule Expert Checks

Just like routine maintenance for vehicles, generator sets benefit from scheduled professional inspections. Regular expert checks help detect hidden issues before they escalate, reducing the risk of unexpected failures during critical operations.

Technicians bring specialized tools and expertise to assess components often overlooked, such as control systems, wiring, and exhaust mechanisms. This proactive approach not only keeps your generator running at peak efficiency but also prevents costly emergency repairs and extends the overall lifespan of your equipment.

Key Takeaway

Keeping your equipment in excellent condition is crucial, especially when power interruptions can disrupt vital operations. By following these maintenance tips to help you maximize the lifespan of your generator set, you can prevent costly breakdowns, ensure dependable performance, and extend the service life of your unit.