Main Components of a Generator Set

Generator sets in the Philippines are intricate machines with multiple components working seamlessly to provide a reliable source of electricity. Each part plays a vital role in ensuring the proper operation of the generator, making it an indispensable tool for various applications.

Engine

At the core of a generator set is the engine, serving as the source of input mechanical energy. The engine's size directly correlates with the generator's maximum power output. Factors such as the type of fuel used, engine design (Overhead Valve vs. non-OHV), and the presence of a Cast Iron Sleeve (CIS) in the engine cylinder influence the generator's durability, efficiency, and operational specifics.

Alternator

Also known as the 'genhead,' the alternator converts mechanical input from the engine into electrical output. Components like the stator and rotor work together to induce a voltage difference, producing the generator's alternating current (AC) output. Considerations like metal versus plastic housing, ball bearings versus needle bearings, and a brushless design impact the durability and maintenance requirements of the alternator.

Fuel System

The fuel system ensures the operational continuity of generator sets in the Philippines, with features like pipe connections, ventilation pipes, overflow connections, fuel pumps, fuel water separators, fuel filters, and fuel injectors. Proper fuel system maintenance and adherence to safety protocols are essential for seamless generator functionality.

Voltage Regulator

The voltage regulator is crucial for maintaining a stable output voltage. The cyclical process involves converting AC voltage to DC, then back to AC, ensuring a continuous and controlled generation of electricity. Factors like the conversion process, exciter windings, rotating rectifiers, and the rotor/armature influence the generator's ability to regulate voltage effectively.

Cooling and Exhaust Systems

The cooling and exhaust systems are crucial components of a generator. The cooling system dissipates heat during continuous usage through various methods, with regular checks on coolant levels and proper ventilation essential for longevity. Simultaneously, the exhaust system manages toxic fumes, requiring proper installation, adherence to safety regulations, and careful material selection to prevent hazards like carbon monoxide poisoning.

Lubrication System

Generator engines require lubrication for smooth operations and durability. Routine checks for oil levels, leakages, and timely oil changes contribute to the longevity of the generator's moving parts. Regular maintenance of the lubrication system ensures optimal performance and prevents potential damage to the generator engine.

Battery Charger

The battery-operated start function of a generator set in the Philippines relies on a battery charger to maintain the battery's charge. Precise float voltage control ensures optimal battery health without manual adjustments, enhancing the generator's reliability.

Control Panel

The control panel serves as the user interface, housing electrical outlets and controls. Features like electric start/shut-down, engine gauges, generator gauges, and other controls provide users with operational insights and control options, enhancing the generator's user-friendliness.

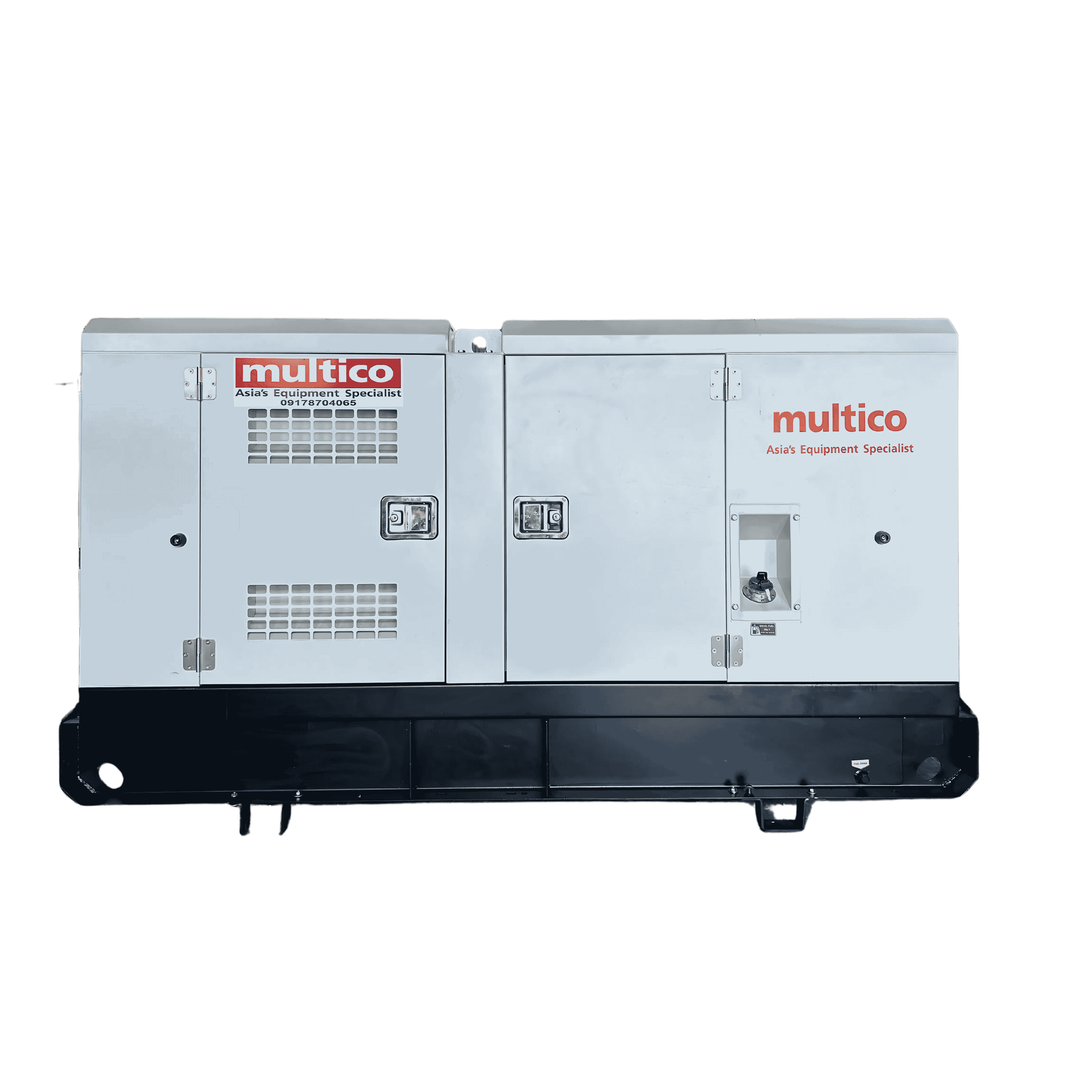

Frame

The frame serves as the structural base support for the generator, ensuring stability and allowing for proper grounding. Whether portable or stationary, the customized housing provides a secure foundation for the generator's components.